How Ballpoint Pens Are Made: A Step-by-Step Look Inside the Manufacturing Process

The ballpoint pen is one of the most common yet remarkable tools ever invented. From schools and offices to homes and industries, this small instrument plays a big role in our daily lives. But have you ever wondered how these pens are made — how the ink flows so smoothly, how the tip works so perfectly, or how thousands of identical pens are produced with precision?

At Vinayak Writing Instruments, based in Keshod, Gujarat, we take pride in crafting high-quality ballpoint pens that blend accuracy, durability, and design. In this post, we’ll take you behind the scenes and show you exactly how a ballpoint pen is made — step by step.

🖋️ The Magic Behind Every Ballpoint Pen

Before we dive into the process, it’s worth understanding what makes a ballpoint pen unique.

Unlike fountain or gel pens, ballpoint pens use oil-based ink that dries quickly and flows evenly through a tiny metal ball at the tip. This design ensures smooth, smudge-free writing that lasts longer — making it ideal for everyday use.

Producing such precision requires expertise, technology, and strict quality control — all of which form the foundation of Vinayak Writing Instruments’ manufacturing philosophy.

⚙️ Step 1: Designing and Planning

Every great product starts with design.

Our design team begins by conceptualizing pen models — whether it’s a Tik Tik Pen, Designer Ball Pen, DF Pen, or Office Pen. We focus on:

-

Ergonomic comfort: ensuring easy grip and smooth writing

-

Aesthetic appeal: creating stylish designs for modern users

-

Functional durability: selecting materials that last

Once the design is finalized, 3D models and technical drawings are prepared. These serve as blueprints for the next stage — production.

🧩 Step 2: Selecting High-Quality Materials

The next crucial step is choosing the right materials. At Vinayak, we use premium-grade plastic for pen barrels and caps to ensure strength, shine, and flexibility.

The tip (or nib) is usually made from brass, steel, or tungsten carbide, as these metals offer precision and long life.

We also select high-quality ink that flows consistently and resists drying — key to a smooth writing experience.

This focus on materials ensures that every pen meets national and international quality standards.

🧑🏭 Step 3: Injection Molding – Shaping the Pen Body

The heart of pen manufacturing lies in injection molding — the process of shaping the pen’s plastic components.

Here’s how it works:

-

Plastic granules are fed into an injection molding machine.

-

They are heated until they melt into a thick, flexible liquid.

-

The molten plastic is injected into molds shaped like pen barrels, caps, and grips.

-

Once cooled, the molds are opened to release the finished parts.

At Vinayak Writing Instruments, we use advanced molding machines that ensure precise dimensions, smooth surfaces, and zero defects.

🧠 Step 4: Manufacturing the Refill

The refill — or ink cartridge — is the pen’s core component. It’s what makes writing possible.

The refill consists of:

-

A plastic tube that holds the ink

-

A metal tip containing the ball mechanism

-

A tiny spring (in some models) for smooth ink flow

The process:

-

The refill tubes are cut to the desired length.

-

The tip assembly is attached at one end.

-

Ink is injected into the refill under controlled pressure.

-

The other end is sealed using heat or a small plug.

Vinayak’s refills undergo strict leakage, flow, and endurance tests to ensure long-lasting and consistent writing.

💧 Step 5: Ink Preparation and Filling

Ink is the lifeblood of every pen. Our team carefully formulates oil-based inks in various colors — ensuring they flow smoothly, don’t clog, and dry instantly on paper.

The ink is filled using automatic filling machines that maintain consistent ink levels in every refill. Each batch is checked for viscosity, density, and color accuracy before use.

By maintaining this quality control, Vinayak ensures your pen never skips, leaks, or fades — no matter how long you write.

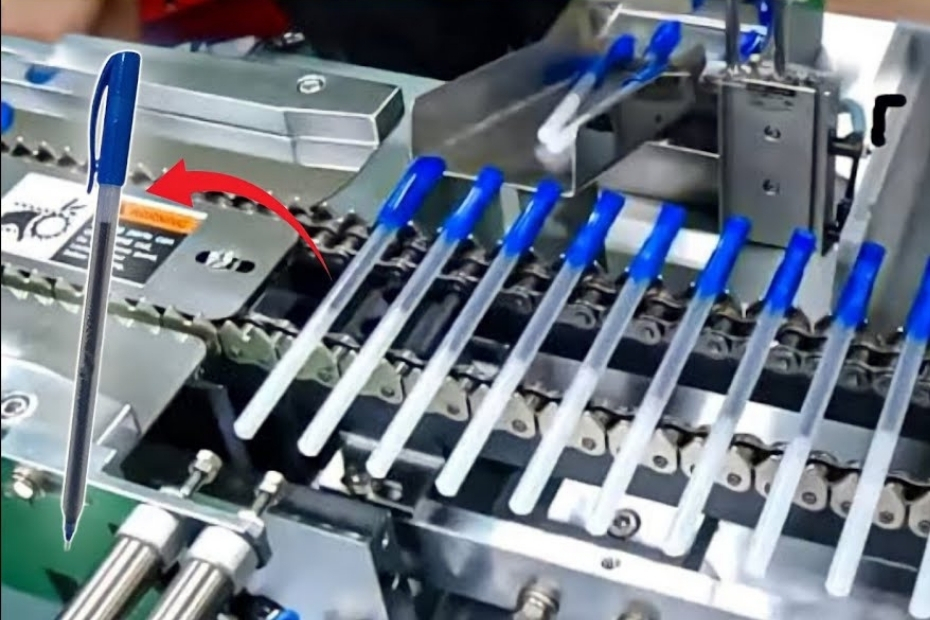

🧰 Step 6: Assembling the Pen

Once all components are ready — the barrel, cap, tip, and refill — the next stage is assembly.

This can be manual or automated, depending on the model.

Typical assembly process:

-

The refill is inserted into the pen barrel.

-

The tip is fitted securely.

-

The spring (for retractable models) is added.

-

The cap or click mechanism is attached.

Every pen is checked for proper alignment and movement to ensure smooth operation.

Vinayak’s experienced team ensures that each pen feels balanced, sturdy, and ready to write the moment you pick it up.

🔍 Step 7: Quality Testing and Inspection

Before any pen leaves our facility, it must pass a series of strict quality control tests.

We test for:

-

Ink flow consistency

-

Tip durability

-

Leakage resistance

-

Smoothness and comfort during writing

-

Cap fit and click function

Each pen is also visually inspected to ensure it meets our aesthetic and functional standards.

This attention to detail has helped Vinayak Writing Instruments earn the trust of customers across India.

📦 Step 8: Branding, Packaging, and Distribution

The final stage involves branding and packaging.

Each pen is printed with the Vinayak logo and product details using high-precision printing machines. The pens are then packaged in boxes or blister packs, depending on order type.

We use secure, eco-friendly packaging to ensure the pens reach customers in perfect condition.

Thanks to our strong logistics network, Vinayak guarantees safe and on-time delivery across India — whether it’s a small local order or a large-scale shipment.

🌱 Step 9: Sustainability and Future Innovations

At Vinayak, we believe that great products should also be environmentally responsible.

We are continuously exploring ways to:

-

Develop refillable and recyclable pens

-

Minimize plastic waste during production

-

Use energy-efficient machinery

Innovation never stops — from sleek designs to eco-friendly solutions, we’re shaping the future of writing instruments in India and beyond.

✨ Conclusion: Precision in Every Pen

The journey of a ballpoint pen — from raw plastic to a finished product — is a blend of science, engineering, and craftsmanship. Each stage, from molding and ink filling to testing and packaging, plays a vital role in delivering the smooth writing experience you love.

At Vinayak Writing Instruments, we combine years of experience with cutting-edge technology to produce pens that are not only affordable but also durable, stylish, and precise. Every pen we make tells a story of quality, innovation, and trust.

Whether it’s a student jotting notes, a professional signing deals, or an artist sketching ideas — a Vinayak pen is built to inspire every hand that holds it.